To install a pneumatic door closer, follow these steps: Position the closer on the door, align it with the jamb bracket, and mark the holes. Drill pilot holes, attach the closer with screws, and adjust the tension for smooth operation.

Welcome to our guide on how to install a pneumatic door closer. A pneumatic door closer is an efficient and effective mechanism that helps ensure the door closes automatically and securely. Whether you are looking to install a new door closer or replace an existing one, this step-by-step guide will provide you with all the essential information you need to complete the installation successfully.

By following these simple instructions, you can have a pneumatic door closer installed in no time, providing convenience and peace of mind for your home or business. So let’s get started and learn how to install a pneumatic door closer.

Key Components Of A Pneumatic Door Closer

When it comes to installing a pneumatic door closer, understanding its key components is essential for a successful installation. A pneumatic door closer is a device that ensures controlled closing of a door, preventing it from slamming shut and providing convenience for users. Let’s take a closer look at the key components that make up a pneumatic door closer:

Cylinder

The cylinder of a pneumatic door closer is a vital component responsible for regulating the flow of air and controlling the door’s closing speed. It is a cylindrical housing, usually made of durable materials such as aluminum or stainless steel. Inside the cylinder, there is a movable piston that interacts with the door closer’s other components.

Piston

The piston is a moving part housed within the cylinder. It is responsible for adjusting the force and velocity applied to the door during its closing motion. When the door is opened, the piston compresses air within the cylinder. As the door is released, the air pressure pushes the piston, causing the door to close gradually and without excessive force.

Spring

An integral component of a pneumatic door closer is the spring. The spring acts as a counterbalance, providing resistance to the door’s closing motion. It helps the piston in controlling the closing speed and allows for smooth and controlled movement. The type and strength of the spring used in a pneumatic door closer depend on the weight and size of the door it will be installed on.

Valve

The valve of a pneumatic door closer is responsible for regulating the flow of air entering and leaving the cylinder. It controls the speed at which the door closes and ensures a consistent and controlled closing motion. The valve allows for adjustments to be made, allowing for customization of the door closing speed to suit the specific requirements of the installation.

By understanding these key components of a pneumatic door closer, you can ensure a successful installation and enjoy the convenience and safety provided by this essential device.

How Pneumatic Door Closers Work

When it comes to ensuring the safety, convenience, and functionality of your doors, a pneumatic door closer is an essential component. These door closers work by utilizing air pressure to control the closing and opening of the door, ensuring a smooth and controlled motion. If you’re looking to install a pneumatic door closer, understanding how it works is crucial to ensure proper installation and functionality. In this section, we’ll break down the process step by step, focusing on how pneumatic door closers work.

Step 1: Closing the door

To start the installation process, the first step is closing the door. It’s important to ensure that the door is properly aligned and fits well within its frame. This step ensures that the pneumatic door closer functions optimally and provides the desired results.

Step 2: Controlling the speed

Once the door is closed, the next step is to control the speed at which it closes. Pneumatic door closers come with adjustable speed settings, allowing you to customize the closing speed according to your preferences. This feature is particularly useful in high-traffic areas where a slower or faster closing speed may be required.

Step 3: Preventing slamming

Nobody wants a door that slams shut loudly. Pneumatic door closers are designed to prevent slamming by employing hydraulic damping technology. This technology ensures that the door closes gradually, reducing the risk of accidental injuries, damage to the door, and disturbance caused by loud slamming noises.

Step 4: Adjusting the tension

To ensure that the pneumatic door closer operates smoothly and efficiently, it’s essential to adjust the tension. Proper tension adjustment ensures that the door closes fully and securely, without any gaps or resistance. This step helps to maintain the integrity of the door structure and keeps it in good condition over time.

Overall, installing a pneumatic door closer is a straightforward process that can enhance the convenience and safety of any door. By following these steps and understanding how pneumatic door closers work, you can ensure a successful and optimized installation.

Factors To Consider Before Installing A Pneumatic Door Closer

When it comes to installing a pneumatic door closer, there are several important factors to consider in order to ensure smooth operation and maximum functionality. From door size and weight to the required closing force, each aspect plays a crucial role in the successful installation of a pneumatic door closer. Additionally, the door’s usage and environment, as well as the desired aesthetics and finish, are also important considerations to keep in mind. Let’s delve into each of these factors in more detail:

Door size and weight

One of the first factors to consider before installing a pneumatic door closer is the size and weight of the door. The door closer needs to be appropriate for the specific door dimensions in order to ensure optimal performance. Assess the door’s measurements and consult the manufacturer’s specifications to determine the suitable size of the door closer.

Door usage and environment

Another crucial factor that should not be overlooked is the door’s usage and environment. Consider whether the door will be used in a commercial or residential setting, as well as the level of traffic it will endure. Additionally, take into account the environment in which the door is located, including exposure to weather elements such as sun, rain, or extreme temperatures. These factors can significantly impact the durability and longevity of the pneumatic door closer.

Required door closing force

The required door closing force is an important consideration as it determines how much force is needed to close the door properly. Different doors have varying sizes and weights, which influences the necessary closing force. By accurately assessing the door’s dimensions and weight, you can select a pneumatic door closer that provides the appropriate closing force, ensuring smooth and secure door operations.

Aesthetics and finish

While the functionality of a pneumatic door closer is crucial, aesthetics and finish also play a significant role in the overall appearance of the door. Consider the desired look and feel, as well as the finish that will match the door’s design and surroundings. Available in various styles and finishes, it is important to choose a pneumatic door closer that enhances the overall aesthetic appeal.

By carefully considering these factors before installing a pneumatic door closer, you can ensure a seamless and successful installation process. Take the time to assess the door size and weight, door usage and environment, required door closing force, as well as the desired aesthetics and finish. This will help you select the ideal pneumatic door closer that meets all your functional and visual requirements.

Types Of Pneumatic Door Closers

Selecting The Appropriate Type For Your Door

Selecting the appropriate type of pneumatic door closer is crucial to ensure smooth and efficient door operation. With various types available in the market, it’s essential to understand your door and its specific requirements before making a choice. In this section, we will discuss considerations for regular arm type, benefits of parallel arm type, and advantages of top jamb type to help you make an informed decision.

Considerations for Regular Arm Type

The regular arm type pneumatic door closer is the most commonly used option for standard doors. It is suitable for doors that open inwards and have sufficient space for the closer to be mounted on the pull side. Here are a few important considerations to keep in mind when opting for the regular arm type:

- Ensure that the closer is installed at the right height, typically between 9 to 12 inches from the top of the door.

- Check the weight and width of your door to select a closer that can handle the load and ensure proper closing strength.

- Verify the mounting options available for the regular arm type closer, such as regular arm or drop plate, and choose the one that suits your door frame.

Benefits of Parallel Arm Type

The parallel arm type pneumatic door closer offers added benefits, making it a popular choice for various applications. This type is installed on the push side of the door, making it less visually obtrusive. Here are some advantages of choosing the parallel arm type:

- It provides better control over the door’s closing speed, ensuring smooth and controlled operation.

- The parallel arm type closer is more resistant to vandalism or intentional damage due to its location on the push side.

- It offers an aesthetic advantage as it requires less visible mounting hardware.

Advantages of Top Jamb Type

The top jamb type pneumatic door closer is commonly used for doors with limited top rail space. It is mounted on the door frame’s top jamb, offering specific advantages for such installations. Here are a few reasons why the top jamb type might be the right choice for your door:

- It is suitable for doors with a narrow top rail as it requires less space for installation.

- The top jamb type closer allows for easier adjustment of the closing speed and latching action.

- This type provides a secure closing mechanism, ensuring that the door remains closed when not in use.

By considering the specific requirements of your door, such as space availability and door type, you can select the appropriate pneumatic door closer type that will provide optimum functionality and durability. Now that we have explored the considerations for regular arm type, benefits of parallel arm type, and advantages of top jamb type, you can make an informed decision and ensure the smooth operation of your door.

Tools And Materials Required

Installing a pneumatic door closer is a great way to ensure that your door closes smoothly and securely every time. To complete this project, you will need a few essential tools and materials. Let’s take a look at what you’ll need:

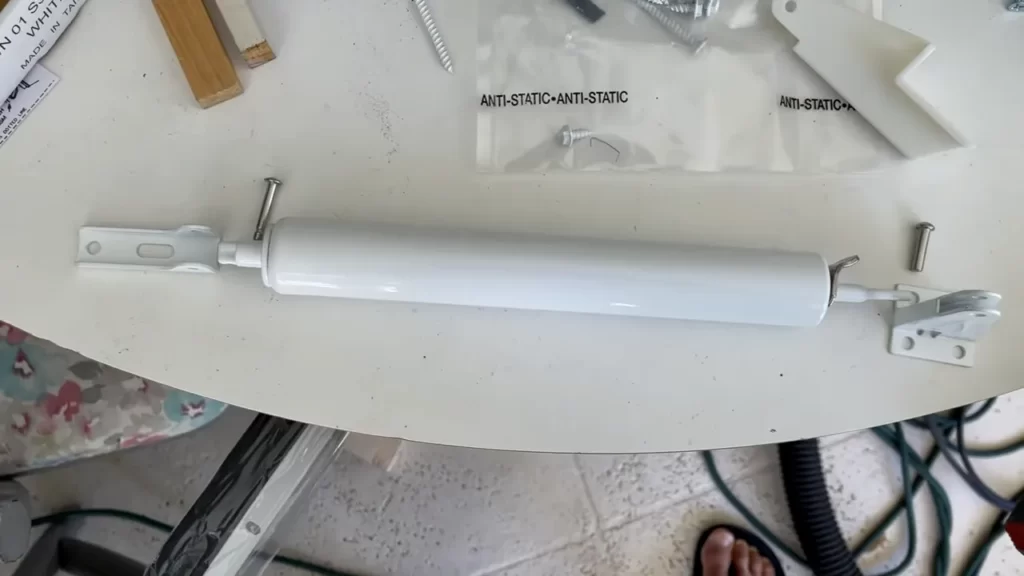

Pneumatic Door Closer

The first item you will need is a high-quality pneumatic door closer. A pneumatic door closer uses air pressure to control the speed at which the door closes. This ensures a smooth and controlled closing, preventing any slamming or damage to the door or frame. Choose a door closer that is suitable for the weight and size of your door.

Screwdriver

A reliable screwdriver is an essential tool for installing a pneumatic door closer. You will need this tool to remove the existing door closer (if applicable) and to secure the new door closer in place. Opt for a screwdriver with a comfortable grip and a variety of interchangeable tips, as you may encounter different types of screws during the installation process.

Drill

A drill is necessary for making pilot holes and securing screws firmly into the door and frame. This tool helps ensure a secure and durable installation. Make sure you have the appropriate drill bits for drilling into the materials of your door and frame, such as wood or metal.

Screws

Speaking of screws, you will need a variety of screws for installing the pneumatic door closer. The specific screws required will depend on the type of door closer you are installing and the materials of your door and frame. Be sure to check the manufacturer’s instructions for recommended screw sizes and types.

Measuring Tape

In order to position the door closer correctly, you will need a measuring tape. This tool allows you to accurately determine the distance between various parts, such as the door closer and the jamb. Taking precise measurements ensures that the door closer functions effectively and that the door operates smoothly.

Having the right tools and materials is crucial for a successful and hassle-free installation of a pneumatic door closer. By gathering these essential items, you will be well-prepared to complete the task with confidence and achieve the desired results.

Preparing The Door And Frame

When it comes to installing a pneumatic door closer, one of the first steps is preparing the door and frame to ensure a seamless installation. In this section, we will walk you through the process of checking the compatibility of the door and frame, measuring and marking the installation points, and pre-drilling holes if necessary.

Checking door and frame compatibility

Before you begin with the installation, it is important to check if the door and frame are compatible with a pneumatic door closer. Start by examining the door and frame for any damages or inconsistencies that may affect the installation. Look for any cracks, dents, or warping on the door or frame that may hinder proper installation. Additionally, check if the door is properly aligned with the frame; an uneven or misaligned door may cause issues during installation and affect the functionality of the pneumatic door closer.

Measuring and marking installation points

Once you have determined that the door and frame are compatible, the next step is to measure and mark the installation points. Begin by measuring the distance between the top of the door and the desired height for the door closer. This measurement will help you determine the optimal placement for the door closer. Using a pencil or marker, make a small mark on the door and frame at the determined height. This mark will serve as a guide during the installation process.

Pre-drilling holes if necessary

Depending on the type of door closer you are installing, you may need to pre-drill holes on the door and frame. This step is essential to ensure a secure and stable installation. Refer to the manufacturer’s instructions for the specific measurements and hole placement. Use a drill and the appropriate drill bit size to create the necessary holes at the marked locations. Be sure to drill straight and avoid applying excessive force, as this can cause damage to the door and frame. Once the holes are drilled, remove any debris or wood shavings for a clean installation surface.

In conclusion, preparing the door and frame is a crucial step in installing a pneumatic door closer. By checking the compatibility of the door and frame, measuring and marking the installation points, and pre-drilling holes if necessary, you can ensure a smooth and successful installation. Following these steps will not only simplify the installation process but also contribute to the proper functionality and longevity of the pneumatic door closer.

Installing The Pneumatic Door Closer

Installing a pneumatic door closer is a simple and effective way to enhance the functionality and safety of your doors. With a pneumatic door closer in place, you can enjoy the convenience of a self-closing door, preventing it from slamming shut and ensuring that it securely latches every time. In this guide, we will take you through the step-by-step process of installing a pneumatic door closer, from attaching the cylinder to the door to adjusting the tension and closing speed. Let’s get started!

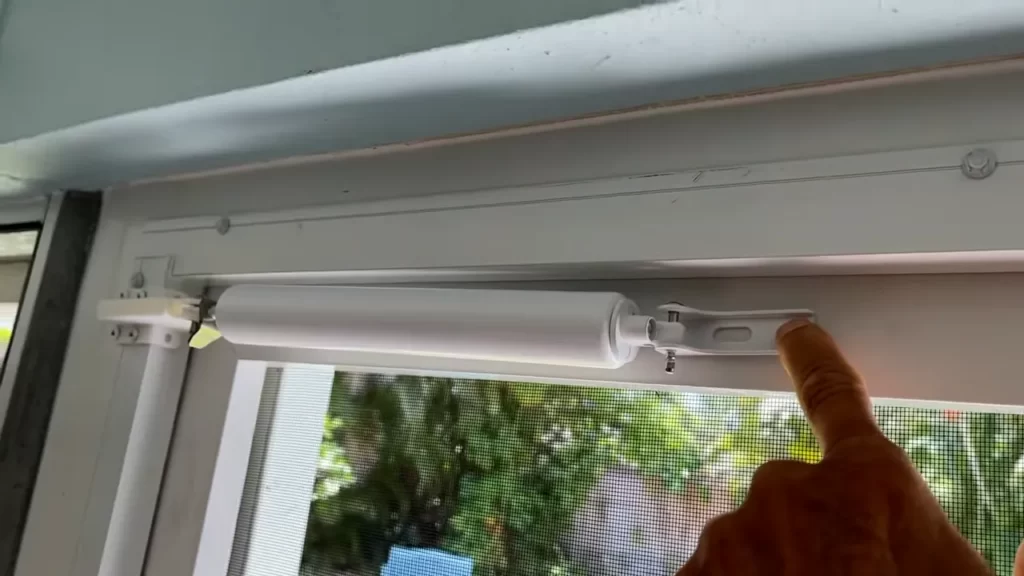

Attaching the cylinder to the door

The first step in installing a pneumatic door closer is to attach the cylinder to the door. The cylinder contains the necessary components to control the closing mechanism of the door. Here’s how you can do it:

- Start by positioning the cylinder bracket against the door, ensuring that it is securely aligned.

- Using a pencil, mark the screw holes on the door to indicate where the bracket will be attached.

- Next, using a drill and the appropriate sized drill bit, create pilot holes at the marked locations.

- Align the bracket with the pilot holes and attach it to the door using the provided screws. Make sure to tighten the screws securely, but be careful not to over-tighten and damage the door.

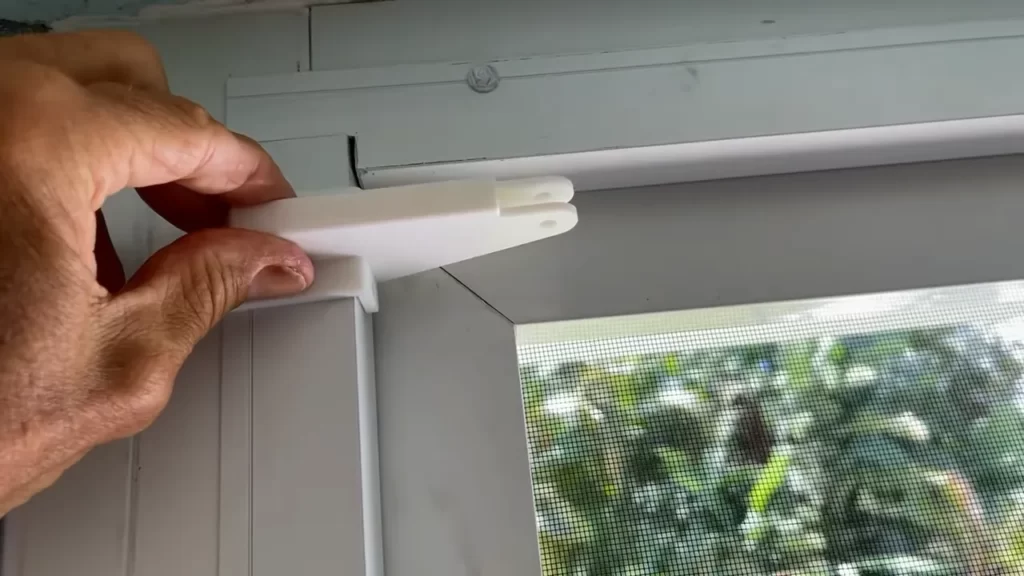

Mounting the bracket on the frame

Once the cylinder is securely attached to the door, the next step is to mount the bracket on the frame. The frame bracket will provide the necessary support for the closing mechanism. Follow these steps:

- Position the frame bracket on the desired location of the door frame and mark the screw holes with a pencil.

- Using a drill and the appropriate sized drill bit, create pilot holes at the marked locations.

- Align the bracket with the pilot holes and attach it to the frame using the provided screws. Ensure that the bracket is firmly secured to the frame to support the door closer’s weight.

Connecting the piston and bracket

With the cylinder and frame brackets in place, it’s time to connect the piston to the brackets. The piston is responsible for controlling the movement of the door and ensuring a smooth closing action. Follow these steps:

- Position the piston so that it aligns with both the cylinder bracket and the frame bracket.

- Insert the piston pin through the holes in the brackets, creating a secure connection.

- Ensure that the piston moves freely and smoothly between the brackets without any obstructions.

Adjusting the tension and closing speed

After connecting the piston and brackets, you will need to adjust the tension and closing speed of the door closer. This step is crucial to ensure that the door closes properly and at a controlled rate. Here’s what you need to do:

- Locate the adjusting screws on the door closer. These screws control the tension and closing speed of the door closer.

- Using a screwdriver, turn the tension screw to increase or decrease the force required to open the door.

- Similarly, use the closing speed screw to adjust the speed at which the door closes. Turning the screw clockwise increases the speed, while turning it anticlockwise decreases the speed.

- Continue adjusting the tension and closing speed until you achieve the desired results. Test the door several times to ensure that it closes smoothly and securely.

By following these steps, you can install a pneumatic door closer and enjoy the benefits of a self-closing and secure door. Remember to refer to the manufacturer’s instructions for specific details and guidelines relevant to your door closer model. Now that you know how to install a pneumatic door closer, it’s time to enhance the functionality and safety of your doors!

Testing And Adjusting The Installed Door Closer

After successfully installing the pneumatic door closer, it is essential to test and adjust its functionality to ensure smooth operation. This step-by-step guide will take you through the process of testing and fine-tuning the installed door closer.

Opening and closing the door to check functionality

The first step in testing the installed door closer is to open and close the door to check its functionality. Begin by opening the door to the desired position and letting go. Observe whether the door closes smoothly and latches properly. If the door slams shut or fails to close fully, adjustments need to be made.

Next, check if the door closes too slowly or too quickly. If the door closes too slowly, it may not latch properly, while closing too quickly could lead to a slamming effect. Both situations can be addressed by making adjustments to the closing speed and latch action.

Fine-tuning the closing speed and latch action

To fine-tune the closing speed of the door, locate the adjustment valve on the door closer. This valve regulates the rate at which the door closes. Turn the adjustment valve clockwise to decrease the closing speed, or counterclockwise to increase it. Make small adjustments and test the door after each change until the desired closing speed is achieved.

In addition to the closing speed, the latch action of the door closer should also be fine-tuned. This ensures that the door fully latches when closed. To adjust the latch action, locate the latch speed control valve and turn it clockwise to increase the latch speed, or counterclockwise to decrease it. Test the door after each adjustment to ensure it latches securely.

Once the closing speed and latch action have been fine-tuned, perform one final test by opening and closing the door multiple times. Ensure that the door closes smoothly, latches securely, and that the closing and latching actions are consistent. If any issues persist, additional adjustments may be necessary.

Summary:

- Open and close the door to check its functionality.

- Adjust the closing speed by turning the adjustment valve clockwise or counterclockwise.

- Fine-tune the latch action by adjusting the latch speed control valve.

- Perform a final test to ensure smooth operation and consistent closing and latching actions.

Door Not Closing Properly

If you have noticed that your door is not closing properly, it may be time to install a pneumatic door closer. A pneumatic door closer is a device that uses air pressure to control the closing speed and force of a door, ensuring that it closes smoothly and securely. In this section, we will cover how to install a pneumatic door closer, focusing specifically on troubleshooting a door that is not closing properly. By following these steps, you can easily resolve any issues and enjoy a properly functioning door.

Adjusting the tension

One common reason for a door not closing properly is incorrect tension on the pneumatic door closer. To adjust the tension, follow these steps:

Step 1:

- Start by locating the adjustment screw on the pneumatic door closer. It is usually located at the end of the closer, near the door hinge.

- Use a screwdriver to turn the adjustment screw clockwise to increase tension or counterclockwise to decrease tension.

- Make small adjustments and test the door after each adjustment to ensure that it is closing properly. Repeat this process until the door closes smoothly and securely.

Checking any obstructions

An obstruction in the door’s path can prevent it from closing properly. Follow these steps to check for any obstructions:

Step 1:

- Inspect the area around the door for any objects, such as furniture or debris, that may be blocking the path of the door.

- If you find any obstructions, remove them and test the door to see if it closes properly.

- Ensure that the door swings freely without any resistance. If there are any loose hinges or worn-out components, consider repairing or replacing them to ensure smooth operation.

Verifying installation correctness

It is essential to ensure that the pneumatic door closer is installed correctly for the door to close properly. Follow these steps to verify the installation:

Step 1:

- Check if the door closer is securely attached to the door frame and door, using the provided mounting hardware.

- Inspect all the screws and make sure they are tightened properly. Loose screws can affect the door’s alignment and overall operation.

- Verify that the arm of the door closer is correctly connected to both the door and the jamb bracket.

By following these steps to adjust the tension, check for any obstructions, and verify the installation correctness, you can easily troubleshoot a door that is not closing properly. Taking the time to ensure that your door is functioning correctly will not only improve the overall appearance of your space but also enhance your security and convenience.

Door Closer Malfunction

Door Closer Malfunction

A well-functioning door closer is important for ensuring the safety and convenience of your premises. However, like any mechanical device, pneumatic door closers can sometimes experience malfunctions. The good news is that many of these issues can be resolved with some simple maintenance and troubleshooting. In this article, we will explore two common door closer malfunctions and provide step-by-step instructions on how to fix them.

Cleaning and lubricating the mechanism

One of the main reasons why a door closer may malfunction is due to dirt and debris that accumulate over time. When these particles clog the mechanism, it can affect the smooth operation of the closer, resulting in uneven closing or even complete failure.

To clean and lubricate the door closer mechanism, follow these steps:

- Start by removing the closer cover or panel to access the internal components.

- Inspect the mechanism for any visible dirt, dust, or debris. Use a soft brush or compressed air to remove these particles gently.

- Once the mechanism is clean, apply a suitable lubricant to the moving parts. Be sure to use a lubricant specifically designed for door closers to prevent damage.

- Ensure that the lubricant is evenly distributed and reaches all the necessary components.

- Replace the closer cover or panel and test the door closer to check if the malfunction has been resolved.

Replacing worn-out components

Over time, some components of the door closer may wear out and need to be replaced. The most common parts that may need attention include the spring, arm, or hydraulic cylinder.

To replace worn-out components, follow these steps:

- Refer to the manufacturer’s instructions to identify the specific components that need replacement and the appropriate replacement parts.

- Securely hold the door in place or have someone assist you to ensure it doesn’t move during the process.

- Remove the worn-out component using the appropriate tools. This may involve unscrewing or disconnecting it from other parts of the door closer.

- Install the new component, aligning it correctly with the other parts of the door closer.

- Tighten any screws or connections to secure the new component in place.

- Test the door closer to ensure it is functioning properly and adjust any settings if necessary.

By regularly cleaning and lubricating the mechanism and promptly replacing worn-out components, you can extend the lifespan of your door closer and minimize the chances of malfunctions. Remember to always refer to the manufacturer’s instructions for specific guidance, as different models and brands may have slightly different procedures.

Door Closer Making Noise

Checking for Loose Screws

If your pneumatic door closer is making noise, one of the first steps you should take is to check for any loose screws. Over time, constant use and weather conditions can cause screws to become loose. This can result in unnecessary noise when the door closer operates. To check for loose screws, follow these simple steps:

- Start by inspecting the door closer and identifying all the screws

- Using a screwdriver, gently tighten any screws that appear to be loose

- Ensure that all screws are securely tightened, but be careful not to overtighten as it may cause damage

Lubricating Moving Parts

Another common cause of noise in pneumatic door closers is lack of lubrication. Over time, the moving parts of the closer can become dry and start rubbing against each other, resulting in unwanted noise. To address this issue, it is crucial to lubricate the moving parts regularly. Here’s how:

- Use a lubricant specifically designed for door closers (e.g., silicone-based lubricant)

- Apply a small amount of lubricant to the hinges and other moving parts of the door closer

- Make sure to wipe off any excess lubricant to prevent dirt and debris buildup

Regularly lubricating the moving parts of your pneumatic door closer will not only minimize noise but also prolong its lifespan.

Regular Inspection And Cleaning

Regular inspection and cleaning of your pneumatic door closer is essential to ensure its smooth and efficient operation. Over time, dirt and debris can accumulate, causing the closer to malfunction or wear out prematurely. By performing routine maintenance, you can prolong the lifespan of your pneumatic door closer and enjoy reliable functionality for years to come. This section will guide you step-by-step through the process of removing dirt and debris, inspecting for wear and tear, and lubricating your door closer as needed.

Removing Dirt and Debris

Before conducting any inspection or cleaning, it is important to make sure the area around the door closer is clear of any obstructions. Remove any loose objects, such as leaves or sticks, that may have accumulated near the closer. It is also important to ensure that the closer itself is free from dirt and debris. This can be done by gently wiping the surface of the closer with a clean cloth or using a soft brush to remove any particles that may be stuck. Taking the time to remove dirt and debris will help prevent any interference with the closer’s operation and keep it functioning smoothly.

Inspecting for Wear and Tear

Regular inspection is crucial to identify any signs of wear and tear in your pneumatic door closer. Start by visually examining the closer for any visible damage, such as cracks or dents. Pay close attention to the mounting brackets and screws as they can loosen over time, compromising the stability of the closer. Additionally, check the piston rod for any signs of rust or corrosion, as this can affect the door closer’s performance. If you notice any significant damage or deterioration during your inspection, it may be necessary to replace the closer to ensure optimal functionality and security.

Lubricating as Needed

Lubrication is another essential aspect of door closer maintenance. Proper lubrication will help reduce friction and ensure smooth operation of the closer. Use a high-quality lubricant recommended by the manufacturer and apply it to the appropriate parts according to the instructions provided. Pay particular attention to the pivot points and moving parts of the closer. Applying a small amount of lubricant to these areas will help prevent them from becoming stiff or sticking. It is important not to over-lubricate, as excess lubricant can attract dirt and debris and lead to additional problems.

By following these simple steps to remove dirt and debris, inspect for wear and tear, and lubricate your pneumatic door closer as needed, you can maintain its functionality and prolong its lifespan. Regular inspection and cleaning will not only ensure smooth operation but also enhance the overall security and safety of your doors. Incorporate these maintenance practices into your routine and enjoy the benefits of a properly maintained pneumatic door closer.

Replacing Parts Of A Pneumatic Door Closer

If you have noticed that your pneumatic door closer is not functioning optimally, it may be time to replace some of its worn-out components. Replacing these parts can help restore the smooth operation of your door closer, ensuring that it functions properly and enhances the security and convenience of your entryway. In this section, we will discuss how to identify worn-out components and provide guidance on ordering and replacing specific parts.

Identifying worn-out components

In order to replace the parts of your pneumatic door closer, it’s important to first identify which components are worn out or damaged. Here are some signs that indicate the need for replacement:

- Leaking seals: If you notice oil or fluid leaking from the door closer, it may indicate that the seals are worn out and need to be replaced.

- Lack of closing force: If the door closer no longer provides sufficient closing force, it could be due to a worn-out piston or spring.

- Noise or squeaking: Unusual noise or squeaking during the door closing process can be a sign of worn-out bearings or hinges.

- Difficulty in opening or closing: If you find it increasingly difficult to open or close the door, it could indicate the need to replace the arm or the closer’s hardware.

Inspect your pneumatic door closer for any of these signs to determine which specific parts need replacement.

Ordering and replacing specific parts

Once you have identified the worn-out or damaged components, the next step is to order the specific parts for your pneumatic door closer. When ordering, it’s essential to ensure you purchase the correct parts that are compatible with the make and model of your door closer. Here’s a step-by-step process to help you order and replace the parts:

- Identify the make and model: Look for the manufacturer’s label or markings on your existing door closer to determine the make and model. This information will help you find the right parts.

- Research and find a reputable supplier: Look for suppliers or manufacturers that specialize in pneumatic door closer parts. Read reviews and compare prices to ensure you are dealing with a reputable and trustworthy supplier.

- Order the required parts: Place an order for the specific parts you need. Make sure to provide the make and model information to ensure accuracy.

- Receive the parts: Once you receive the ordered parts, carefully inspect them to ensure they match the specifications and are in good condition.

- Replace the worn-out components: Follow the manufacturer’s instructions or consult with a professional, if needed, to replace the worn-out components. Take note of any specific tools or techniques required for the replacement process.

- Test the door closer: After replacing the parts, test the door closer to ensure that it operates smoothly and provides the expected closing force.

By following these steps and replacing the necessary components of your pneumatic door closer, you can ensure its optimal performance and prolong its lifespan.

Extending The Lifespan Of Your Door Closer

Your door closer is an essential component of your entryway, providing convenience and safety by ensuring that your door closes smoothly and securely. To maximize its lifespan and maintain its functionality, it is important to follow some key practices. By avoiding excessive force on the door, keeping the door and closer clean, and performing regular maintenance checks, you can ensure that your door closer continues to operate efficiently for years to come.

Avoiding excessive force on the door

One of the primary causes of premature door closer failure is the application of excessive force on the door. This can lead to stress and strain on the door closer mechanism, causing it to wear out more quickly. To avoid this, pay attention to how much force you apply when opening and closing the door. Encourage individuals passing through to be mindful of the force they exert on the door as well. By adopting a gentle and controlled approach, you can reduce wear and tear on the door closer, ensuring its longevity.

Keeping the door and closer clean

A clean door and door closer not only enhance the appearance of your entryway but also contribute to the smooth operation of the door closer. Over time, dirt, dust, and debris can accumulate on the surface of the door and the closer, impeding its functionality. Regularly clean the door and the closer using a mild soap solution and a soft cloth to remove any dirt or grime. When cleaning, pay special attention to the hinges, arm, and other moving parts of the door closer. By keeping them clean and free from obstructions, you can ensure that your door closer functions optimally.

Performing regular maintenance checks

Regular maintenance checks are crucial for extending the lifespan of your door closer. Inspect the closer periodically to identify any signs of wear, damage, or misalignment. Look for loose screws, worn-out components, or any unusual noises or resistance when opening or closing the door. If you notice any issues, address them promptly by tightening screws, replacing damaged parts, or adjusting the closer’s settings. Refer to the manufacturer’s instructions for specific maintenance guidelines for your door closer model.

By following these practices, you can ensure that your door closer operates smoothly and efficiently, minimizing the risk of premature failure. Implement these steps as part of your routine care for your door closer, and you’ll enjoy the benefits of a long-lasting and reliable entryway solution.

Frequently Asked Questions Of How To Install Pneumatic Door Closer

Which Is Better Pneumatic Or Hydraulic Door Closer?

Pneumatic door closers are better because they provide a smoother closing action, are easier to install, and require less maintenance compared to hydraulic door closers. They also offer adjustable closing speeds, making them suitable for a variety of door sizes.

Do Pneumatic Door Closers Go On Top Or Bottom?

Pneumatic door closers can be installed either on the top or bottom of the door.

How Long Do Pneumatic Door Closers Last?

Pneumatic door closers typically last around 10 to 15 years. With proper maintenance and usage, they can provide reliable and efficient door closure for an extended period of time.

How Do You Adjust The Tension On A Pneumatic Door Closer?

To adjust the tension on a pneumatic door closer, locate the adjustment screw on the closer’s body. Use a screwdriver to turn the screw clockwise to increase tension or counterclockwise to decrease it. Test the door to ensure proper closing and adjust as needed.

How Do I Install A Pneumatic Door Closer?

To install a pneumatic door closer, start by positioning the closer on the top of the door and marking the screw holes. Then, attach the bracket and align the closer. Finally, secure it with screws and adjust the closing speed.

What Tools Do I Need To Install A Pneumatic Door Closer?

To install a pneumatic door closer, you will need a drill, screwdriver, tape measure, pencil, and the necessary screws that come with the door closer.

Conclusion

Installing a pneumatic door closer is a simple and effective way to enhance the functionality and safety of your doors. By following the step-by-step instructions provided in this blog post, you can easily accomplish this task on your own. Remember to choose the right door closer for your specific needs and ensure proper installation for optimal performance.

With a pneumatic door closer, you can enjoy improved energy efficiency, noise reduction, and convenience in your space. So, go ahead and give it a try!